Optical Fiber Sensors

Microstructured Optical Fibres (MOFs), also known as photonic crystal fibres, have been around for about two decades now. B-PHOT has developed expertise in modelling the optical and thermo-mechanical characteristics of different types of MOF and has established a broad portfolio of novel MOF designs for diverse applications including: temperature independent pressure, transverse force and shear strain sensing for structural health monitoring; vibration measurements; dispersion management in telecommunication systems; low bending loss connections in Fibre-To-The-Home systems; amplification and beam delivery in fibre laser systems. In the last years, our research emphasis has been on MOF-based sensors as well as fiber Bragg grating instrumentation projects in numerous applications.

Microstructured optical fibre based sensors

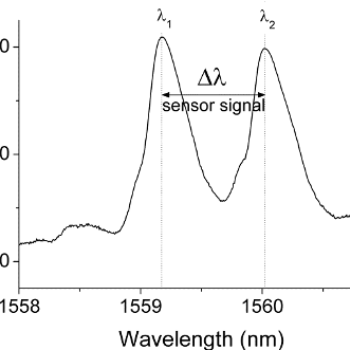

We develop highly birefringent Microstructured Optical Fiber Bragg-grating-based sensors that feature unprecedented sensitivity to pressure and to transverse force, whilst being negligibly sensitive to temperature changes. This development is patented and licensed to industry for application in the field of oil and gas exploitation. B-PHOT uses both in-house and commercially available software for the modelling and design of MOFs. Its laboratories are also fully equipped with state-of-the-art instruments for characterizing MOFs.

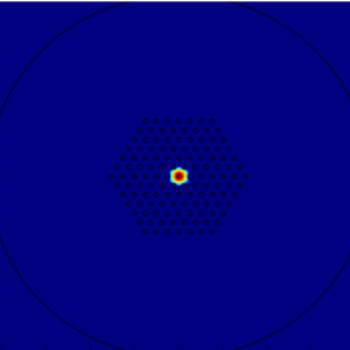

MOF fundamental mode

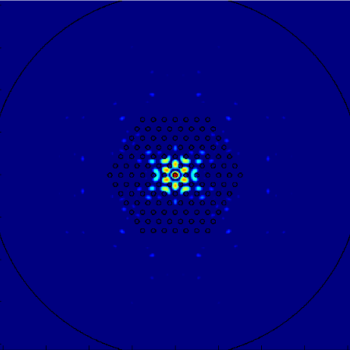

MOF cladding mode

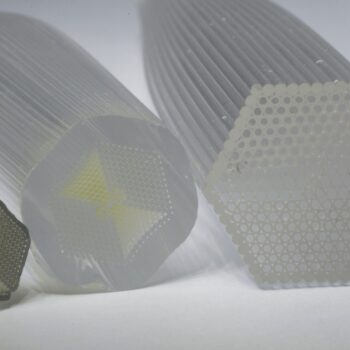

PCF preforms

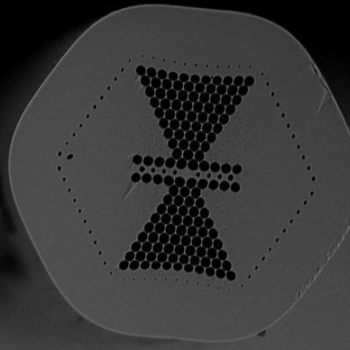

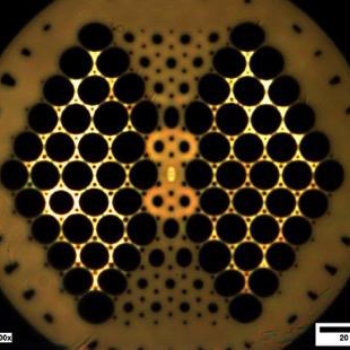

Butterfly FCF

Shear sensing PCF

Mechanical testing of MOF

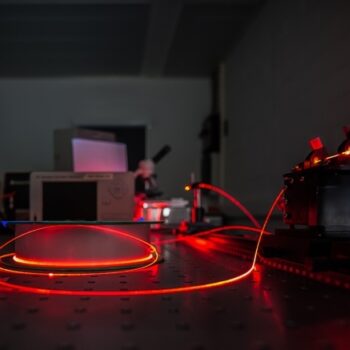

FBG inscription in PCF

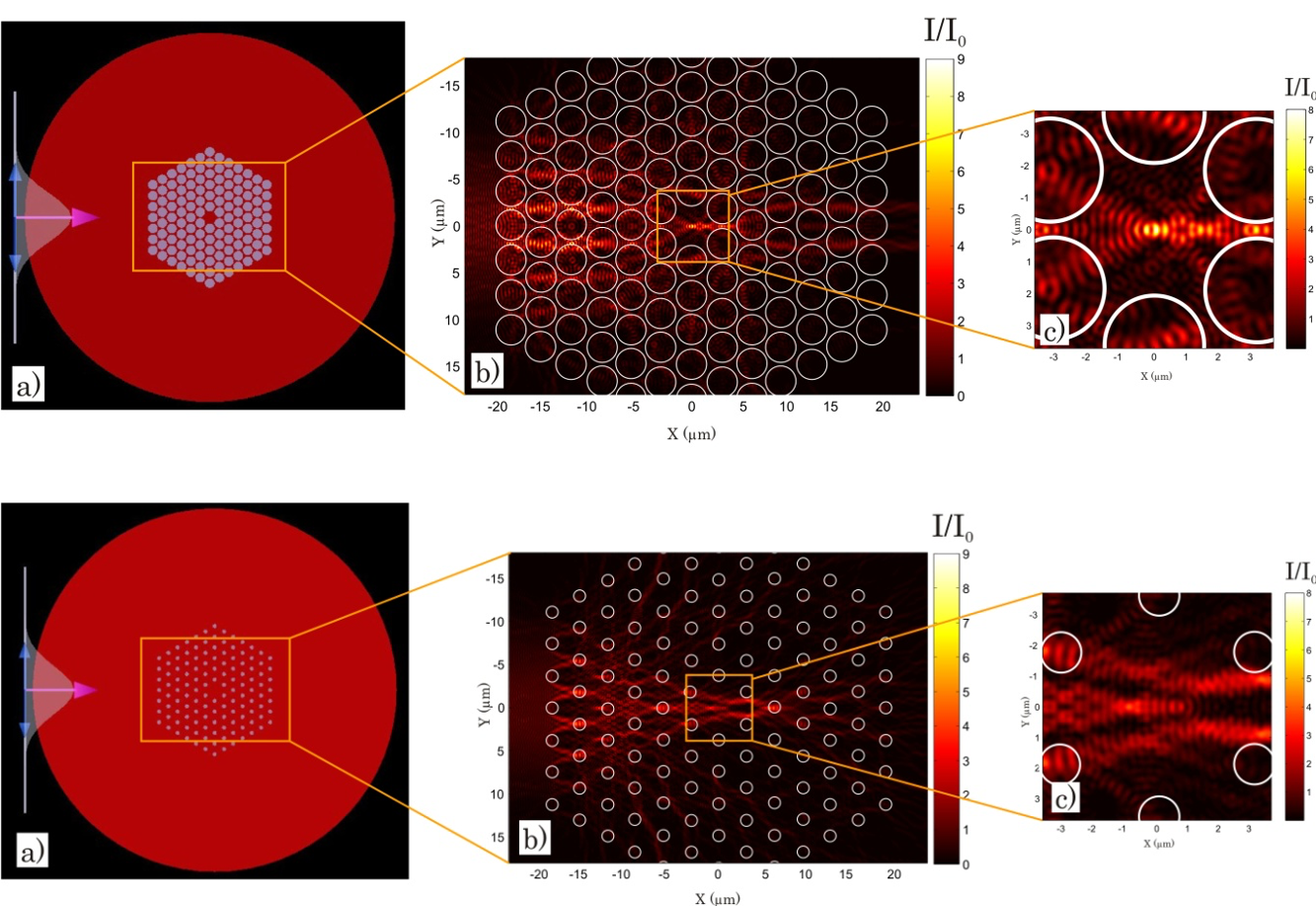

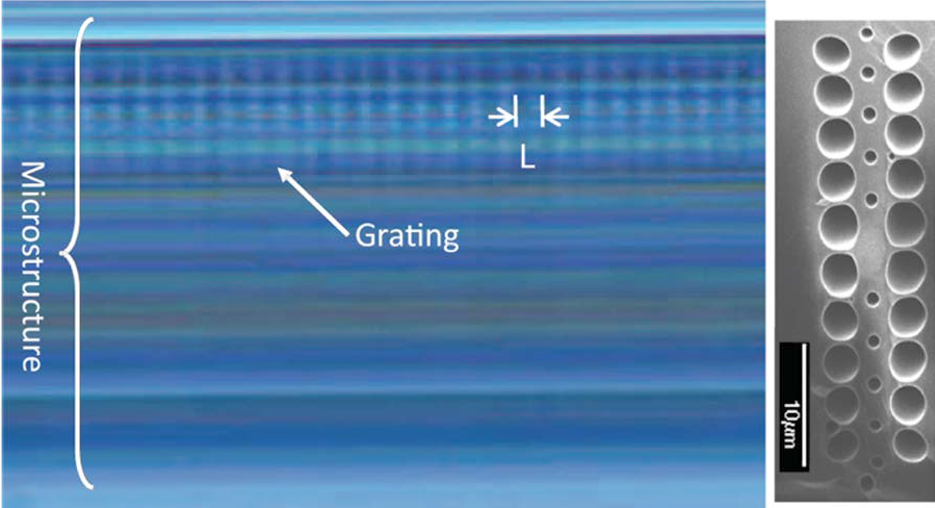

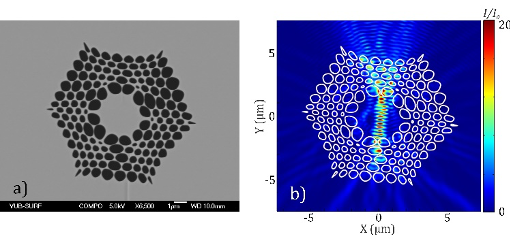

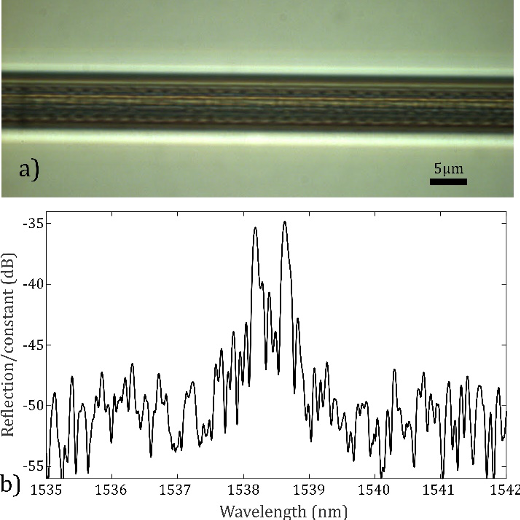

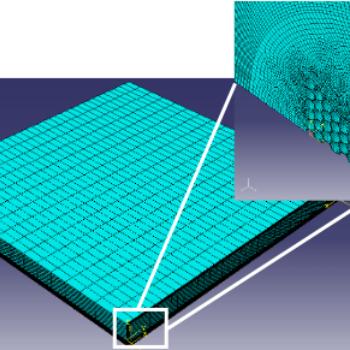

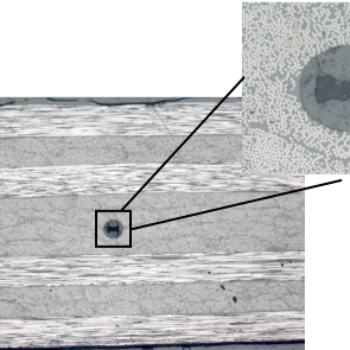

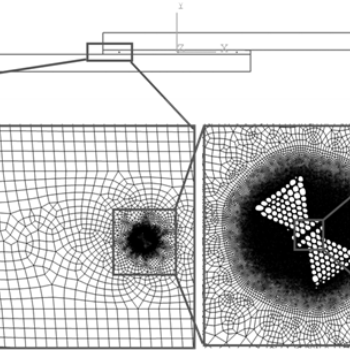

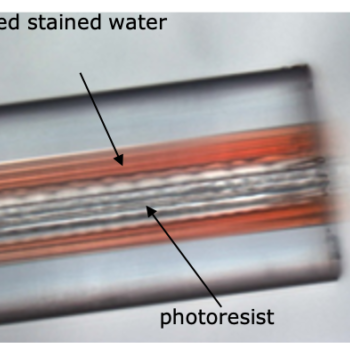

As part of our research on microstructured optical fibers and fiber Bragg grating based sensors therein, we focus on the difficulties and challenges encountered during photo-inscription of such gratings and more specifically on the effect of the air hole lattice microstructure in the cladding of the fibre on the transverse coupling of the coherent writing light to the core region of the fibre. We develop experimental and computational quantities to assess the influence of the photonic crystal lattice on the grating writing efficiency and design and test techniques that have been proposed to mitigate this influence. We even design adaptions to the microstructure in view of enhancing instead of counteracting the multi-photon grating fabrication efficiency.

FDTD simulation

First fs point-by-point FBG in PCF

Optimized PCF

fs grating in optimized PCF

FBG instrumentation for Smart Materials

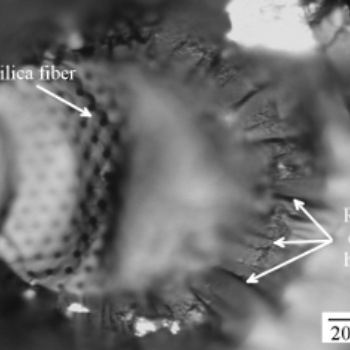

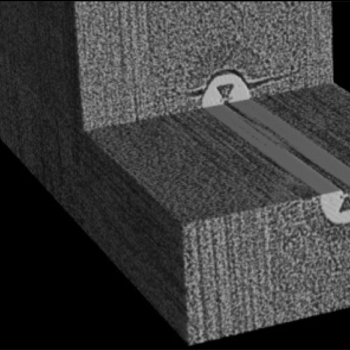

This sensor technology has been adapted to the integration within laminate composite materials and has led to the demonstration of simultaneous measurement of the 3 components of normal strain and to estimate the residual transverse strain inside the composite following the fabrication of the laminate. Recently these Microstructured Optical Fiber-based sensors have enabled measuring shear strain in and quantifying de-bonding of glue joints with industrially relevant resolutions

FEM embedded Butterfly MOF

micro-CT of embedded Butterfly MOF

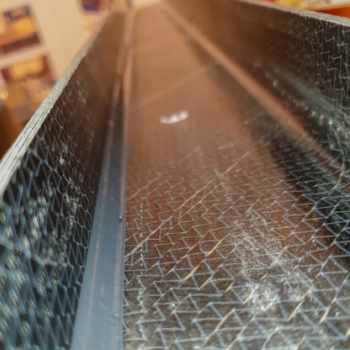

Butterfly MOF in CFRP

FBG in Butterfly MOF

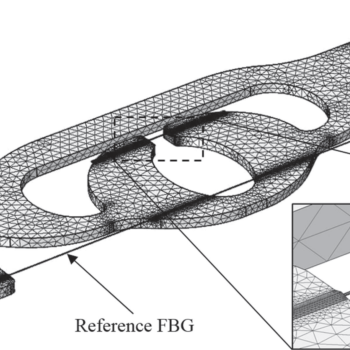

FEM shear sensing in adhesive joint

Adhesive joint monitoring

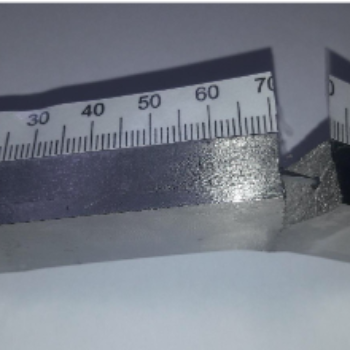

Crack monitoring in 3D printed metals

Surface mounting of FBGs

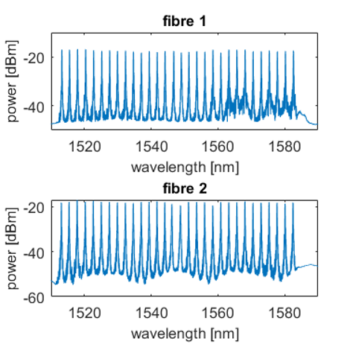

Spectrum of FBG arrays

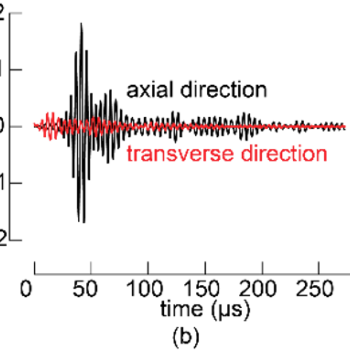

Lamb wave sensing with Butterfly MOF

Thermoset stiffened panel

Damage detection experiments

Thermoplast window frame

C-shaped composite beam

Hinge arm with 3D strain PCF sensor

FBG instrumentation for the Belgian Nuclear Research Center

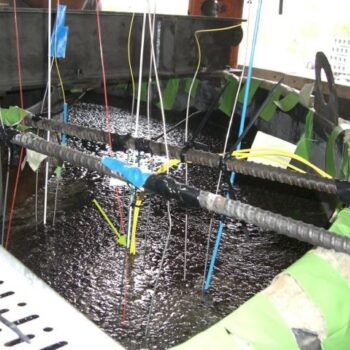

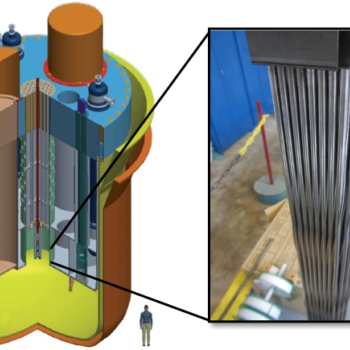

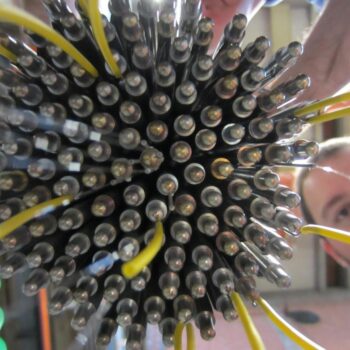

We have a long-standing collaboration with the Belgian Nuclear Research Center. In recent projects we have investigated the structural integrity of a concrete supercontainer for long-term storage of radioactive waste for EURIDICE and we have performed an experimental investigation of flow-induced vibrations in the fuel assembly of MYRRHA - The Multi-purpose hYbrid Research Reactor for High-tech Applications, which result from the circulation of the liquid lead-bismuth eutectic (LBE) mixture that is used as a coolant.

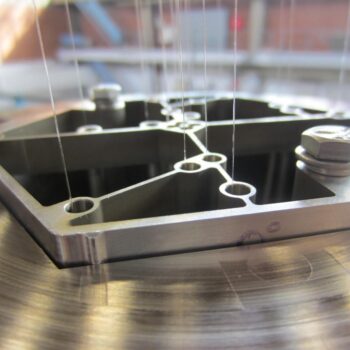

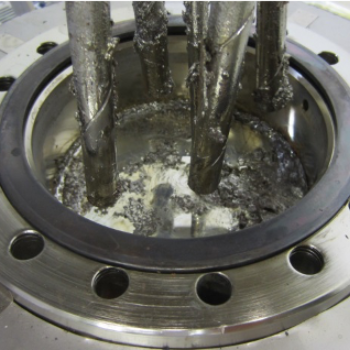

Supercontainer mould

PCF sensor installation

Sensor lead-out from self-compacting concrete

Supercontainer during simulated heating

MYRRHA concept with fuel bundle

FBG instrumentation fuel bundle

Sensor lead-out

Instrumented fuel bundle in lead-bismuth

FBG instrumentation for Smart Infrastructure

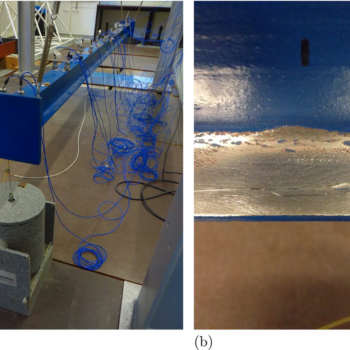

We have developed dedicated strain transducers for FBG-based strain measurements that serve vibration-based damage identification. This is a non-destructive method that enables health monitoring of civil engineering structures. It aims to detect the presence and growth of damage by measuring changes of natural frequencies, damping factors or modal displacements of these structures. This approach typically suffers from the low sensitivity of these natural frequencies and modal displacements to certain types of damage. Modal strains and curvatures can be more sensitive to local damage. However, when considering ambient excitation, the strain amplitudes in concrete civil structures can be in the sub-microstrain range (<1με). Unfortunately, the use of commercially available strain sensors combined with an entry-level interrogator does not allow for quasi-distributed strain measurements below 1 με. By means of an FBG array mounted on our strain transducers, a highly sensitive strain sensor for monitoring bridges became possible and the modal strains could be measured.

Lab tests

FEM strain transducer

Prototype transducer

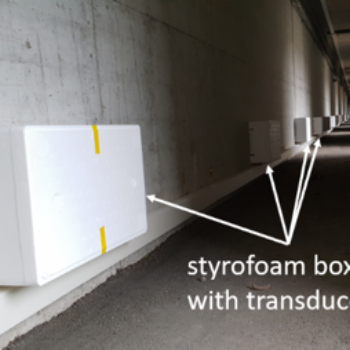

Arbre viaduct

Field installation

Mounted FBG transducer

Transducer array

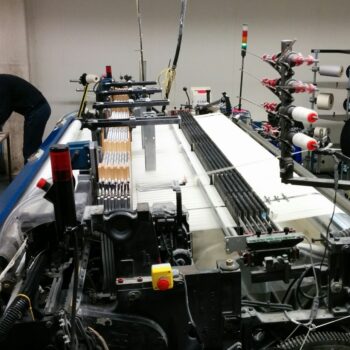

FBG instrumentation for Industry4.0

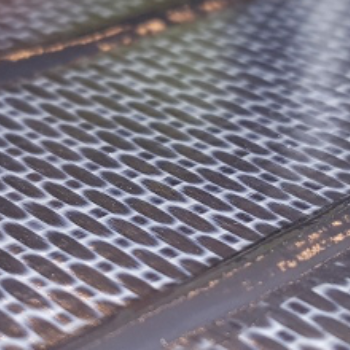

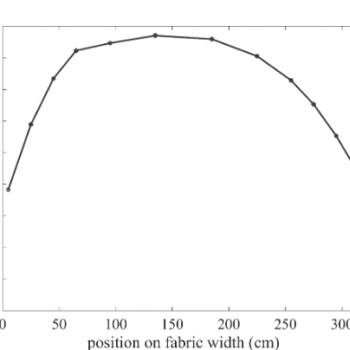

B-PHOT is a Core Lab member of Flanders Make. As part of our involvement we design and test optical fiber sensors for research and industry partners in their transformation to Industry4.0 solutions. In one of these collaborations we have collaborated with PICANOL to provide unique insights in their weaving machines. Optical fibers with fiber Bragg gratings based sensors were woven into the fabrics in the warp and weft directions to provide strain assessments of the weaving operation itself as well as the residual strain in the fabric.

Weaving machine instrumentation

Fabric instrumentation

Fabric instrumentation

Strain in fabric

Biocompatible and biodegradable polymer optical fibers

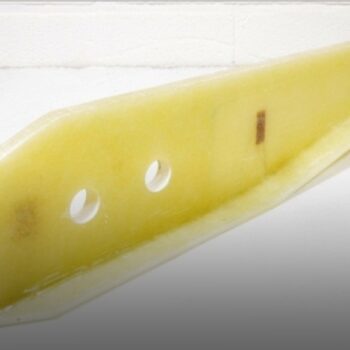

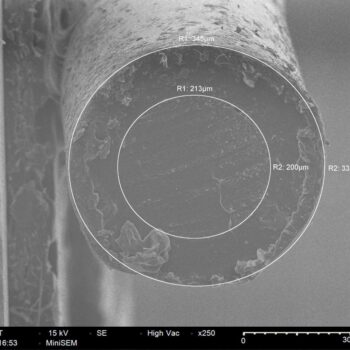

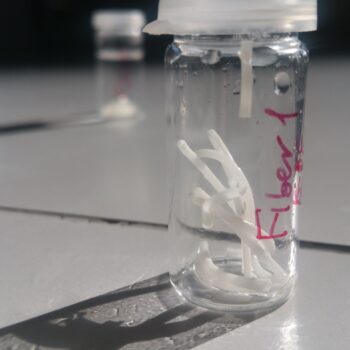

The use of polymers instead of glass can convey unique properties to the optical fibers, such as biocompatibility and biodegradability, which will enable the future use of these photonic devices in the biomedical field. Fabricating such new POFs first requires developing the adequate materials in terms of processability, biocompatibility, optical transparency and thermomechanical stability. We rely on our collaboration with the Polymer Chemistry and Biomaterals Group at Universiteit Gent. Second we design and fabricate the fiber preforms for step-index and air-filled geometries in-house and draw the actual fibers in collaboration with one of our European partners. One of the possible future applications includes light-assisted cell-seeding and subcutaneous treatments.

BioPOF

BioPOF

SEM of core/clad bioPOF

Biodegradation of bioPOF

microstructured POF

microstructured bioPOF

Lab-on-fibre

We have recently started a new research line lab-on-fibre devices for biomedical applications. We aim to overcome the limitations of current lab-in-fibre plasmonic sensors for the detection of cancerous cells in blood samples.

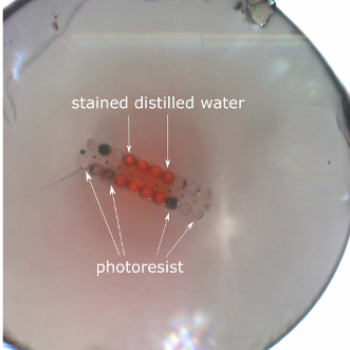

Selective filling of MOF